Similarly, when delivery times are longer, the minimum level is more important to cope with unforeseen events. Falling below the minimum stock level is any business’s worst nightmare. You’re practically telling customers, “Sorry, we’re out,” resulting in dissatisfaction, strained relationships, and missed sales opportunities.

- Utilize inventory aging to effectively categorize your eCommerce products.

- The goal is to strike a balance between maintaining adequate stock levels and minimizing carrying costs.

- Then your order period depends on how quickly you sell the contents of a container (or truck).

- The change saved Rutland £1 million in inventory costs, improved cash flow, and set the stage for future growth.

- Learn how to plan inventory for product bundles and kits in ecommerce.

- There are a few reasons why it’s important to be aware of your minimum inventory levels.

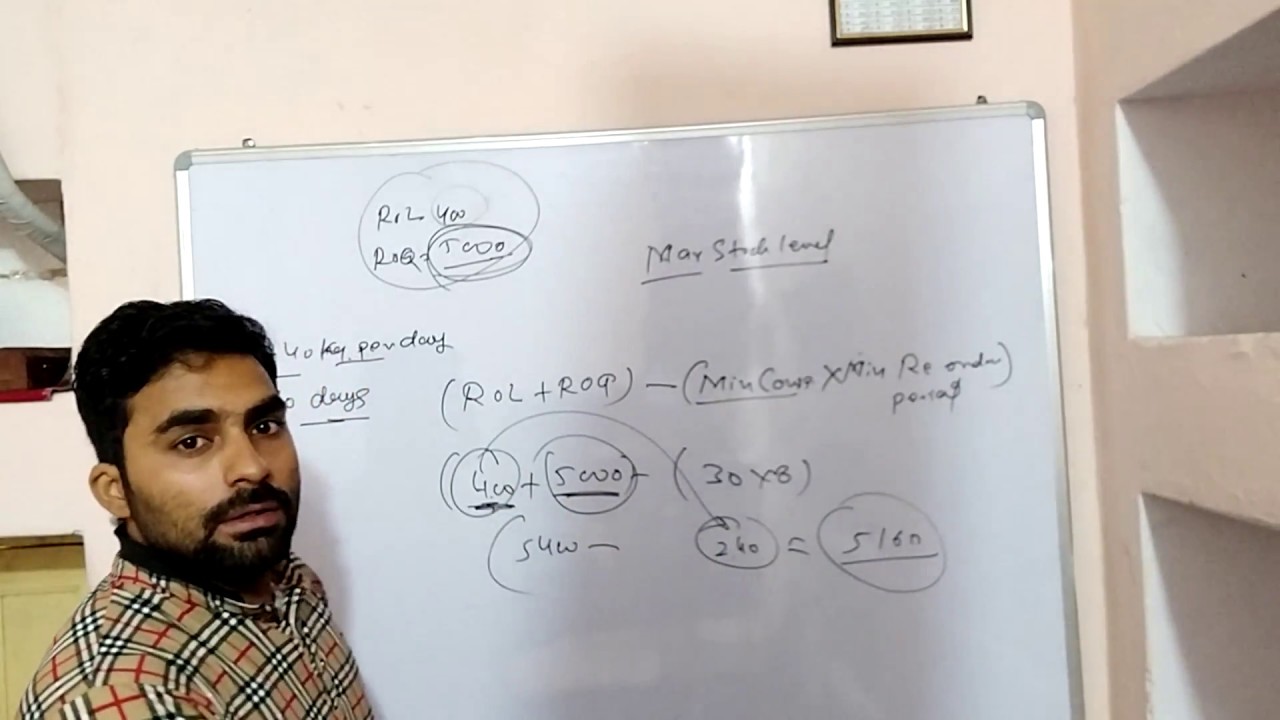

Calculating Minimum Stock Levels

Min and max stock levels are predetermined inventory limits that help businesses maintain optimal stock levels. These predetermined thresholds can be fixed quantities for each item or dynamically adjusted based on sales trends using real-time sales data from a perpetual inventory system. In this post, we take an in-depth look at optimal stock levels in logistics as well as the differences between this concept and minimum and safety stock levels. Plus, we break down the formula for making sure your inventory is in line with demand, the warehouse, and the steady growth of your company.

Maximized Profit Margins

Therefore, have control of everything that enters and leaves your company, lowering sales and keeping an updated file with exact quantities and variations depending on the time of year and festive dates. In addition, the minimum stock offers more security to managers, especially in extraordinary cases, such as the delay of a supplier – which could compromise its image with its loyal public. See the top eBay selling tools available today to help ecommerce companies more effectively scale or run their business on eBay. If you’re overwhelmed by the idea of tracking all these metrics manually, it’s high time to invest in an inventory management solution like SkuVault. To use this method, you must first determine how many units of a product are demanded each day, week, or month.

Leverage real-time analytics to track inventory levels 📈

Get in touch — we’ll provide you with a personalized demo of Easy WMS with all the control and stock management functionalities you need. Reviewing and categorizing stored inventory according to stock turnover will bring to light products that haven’t sold well and are hindering overall stock management. If you are a dropshipper or ecommerce seller, we can build the shopify or wordpress website for you, recommend hot-selling products, sourcing the suppliers, quality inspection and fulfill your order. Before thinking about applying any formula, it is of paramount importance that your store’s inventory is up to date.

Optimal inventory levels ensure you never have too much or too little inventory at any given time. And when a DTC brand maintains that kind of inventory control, they benefit in a myriad of ways. Better awareness of your average stock level can help you plan your supply chain by determining the best time to reorder more goods.

Example of how to calculate optimal inventory level

Learn how GoComet’s software solution can help you maintain better overall inventory management to drive double-digit cost savings in your supply chain. The proper value of products in stock management varies according to the characteristics of the companies. A retail trade, for example, needs a larger stock, as it needs to serve customers immediately, while an industry needs to be more concerned with the amount of raw material and inputs to keep production running. By using the information in this blog post, you can ensure that you always have enough products in stock to meet customer demand.

Longer lead times necessitate higher safety stock levels to ensure adequate stock availability during the lead time. Calculating your minimum inventory levels is a critical part of running a successful business. The digitization of logistics processes has made it possible to automate multiple tasks that used to lead to mistakes and cause operators to lose valuable time.

It’s a simple method to implement, and it can be automated with almost any ERP or WMS. In this way, when a SKU reaches the turbotax discount level, the system issues a notification or automatic replenishment order, relieving managers from carrying out this task. In this guide, we'll explain what a minimum stock level is, how to calculate it with a formula and more. Planning beyond minimum stock figures is crucial for a holistic approach to the replenishment process.

Let’s explore some proven ways to always keep your safety stock on hand, ensuring uninterrupted business continuity. Minimum stock represents the lowest level of inventory a business can maintain while ensuring that demand fluctuations, supply chain disruptions, or unexpected factors do not lead to stockouts. It is meant to prevent disruptions in sales or customer service due to unforeseen circumstances while keeping inventory holding costs low. Optimal inventory levels are somewhere between your minimum and maximum levels. And you need to calculate this number to, well, maintain optimal inventory levels.